Ground-Fault Circuit Interrupters (GFCIs)

What is a GFCI?

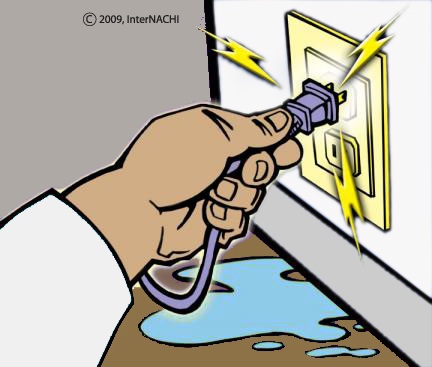

GFCIs are designed to provide protection in such a situation, unlike standard circuit breakers, which guard against overloads, short circuits and ground faults.

GFCIs are designed to provide protection in such a situation, unlike standard circuit breakers, which guard against overloads, short circuits and ground faults.History

The first high-sensitivity system for detecting current leaking to ground was developed by Henri Rubin in 1955 for use in South African mines. This cold-cathode system had a tripping sensitivity of 250 mA (milliamperes), and was soon followed by an upgraded design that allowed for adjustable trip-sensitivity from 12.5 to 17.5 mA. The extremely rapid tripping after earth leakage-detection caused the circuit to de-energize before electric shock could drive a person’s heart into ventricular fibrillation, which is usually the specific cause of death attributed to electric shock.

NEC Requirements for GFCIs

The National Electrical Code (NEC) has included recommendations and requirements for GFCIs in some form since 1968, when it first allowed for GFCIs as a method of protection for underwater swimming pool lights. Throughout the 1970s, GFCI installation requirements were gradually added for 120-volt receptacles in areas prone to possible water contact, including bathrooms, garages, and any receptacles located outdoors.

The 1980s saw additional requirements implemented. During this period, kitchens and basements were added as areas that were required to have GFCIs, as well as boat houses, commercial garages, and indoor pools and spas. New requirements during the ’90s included crawlspaces, wet bars and rooftops. Elevator machine rooms, car tops and pits were also included at this time. In 1996, GFCIs were mandated for all temporary wiring for construction, remodeling, maintenance, repair, demolition and similar activities and, in 1999, the NEC extended GFCI requirements to carnivals, circuses and fairs.

The 2008 NEC contains additional updates relevant to GFCI use, as well as some exceptions for certain areas. The 2008 language is presented here for reference.

2008 NEC on GFCIs

100.1 Definition

100.1 Definitions. Ground-Fault Circuit Interrupter. A device intended for the protection of personnel that functions to de-energize a circuit or portion thereof within an established period of time when a current to ground exceeds the values established for a Class A device.

FPN: Class A ground-fault circuit interrupters trip when the current to ground has a value in the range of 4 mA to 6 mA. For further information, see UL 943, standard for Ground-Fault Circuit Interrupters.

210.8(A)&(B) Protection for Personnel

210.8 Ground-Fault Circuit Interrupter Protection for Personnel.

(A) Dwelling Units. All 125-volt, single-phase, 15- and 20-ampere receptacles installed in the locations specified in (1) through (8) shall have ground-fault circuit-interrupter protection for personnel.

(1) bathrooms;(2) garages, and also accessory buildings that have a floor located at or below grade level not intended as habitable rooms and limited to storage areas, work areas, and areas of similar use;Exception No. 1: Receptacles not readily accessible.

Exception No. 2: A single receptacle or a duplex receptacle for two appliances that, in normal use, is not easily moved from one place to another and that is cord-and-plug connected in accordance with 400.7(A)(6), (A)(7), or (A)(8).

Receptacles installed under the exceptions to 210.8(A)(2) shall not be considered as meeting the requirements of 210.52(G)

(3) outdoors;

Exception: Receptacles that are not readily accessible and are supplied by a dedicated branch circuit for electric snow melting or deicing equipment shall be permitted to be installed in accordance with the applicable provisions of Article 426.

(4) crawlspaces at or below grade level.

Exception No. 1: Receptacles that are not readily accessible.

Exception No. 2: A single receptacle or a duplex receptacle for two appliances that, in normal use, is not easily moved from one place to another and that is cord-and-plug connected in accordance with 400.7(A)(6), (A)(7), or (A)(8).

Exception No. 3: A receptacle supplying only a permanently installed fire alarm or burglar alarm system shall not be required to have ground-fault circuit interrupter protection.

Receptacles installed under the exceptions to 210.8(A)(2) shall not be considered as meeting the requirements of 210.52(G)

(6) kitchens, where the receptacles are installed to serve the countertop surfaces;

(7) wet bar sinks, where the receptacles are installed to serve the countertop surfaces and are located within 6 feet (1.8 m) of the outside edge of the wet bar sink;

(8) boathouses;

(B) Other Than Dwelling Units. All 125-volt, single-phase, 15- and 20-ampere receptacles Installed in the locations specified in (1), (2), and (3) shall have ground-fault circuit interrupter protection for personnel:

(1) bathrooms;

(2) rooftops;

Exception: Receptacles that are not readily accessible and are supplied by a dedicated branch circuit for electric snow-melting or de-icing equipment shall be permitted to be installed in accordance with the applicable provisions of Article 426.

(3) kitchens.

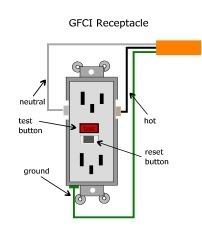

Testing Receptacle-Type GFCIs

re they are working properly and are providing protection from fatal shock.

re they are working properly and are providing protection from fatal shock.If the “RESET” button does not pop out, the GFCI is defective and should be replaced.